Cold storage: a low-temperature special warehouse built by artificial refrigeration, whose function is to freeze and store perishable goods, or to cool down certain process equipment and environment.

It can be roughly divided into the following types: food preservation storage, frozen food cold storage, cooling storage, freezing storage, ice storage, process cold storage, etc.

Cold storage is divided into civil construction and prefabricated types according to the structural form

Application of civil construction cold storage: because of its good insulation effect and relatively less impact from the outside world, it is widely used in some large

vegetable and fruit production, wholesale bases and some meat and poultry processing plants.

Application of prefabricated cold storage: prefabricated cold storage is characterized by simple structure, easy installation, short construction period, light weight, high strength and beautiful appearance. It is now more and more widely used in business, especially in hotels, restaurants, vegetable markets and commercial food circulation.

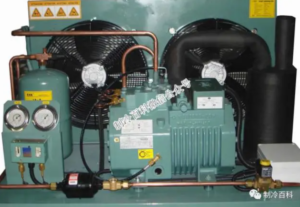

1. Compressor:

Compression refrigeration unit (air-cooled unit)

2. Condenser:

Condenser: transfers the heat of high-temperature and high-pressure refrigerant vapor from the compressor to the surrounding medium-water or air, and cools it into low-temperature and high-pressure liquid. It is a necessary device to output heat to the outside of the system.

3. Condenser type:

Air cooling type (referred to as air cooling or wind cooling); water cooling type (referred to as water cooling); evaporative type.

4. Storage:

A container for storing and supplying high-pressure liquid refrigerant, storing liquid refrigerant from the condenser, and adjusting and stabilizing the circulation volume of refrigerant to adapt to changes in working conditions.

Usually installed behind the condenser (air-cooled unit), water-cooled units with liquid storage function generally do not have a liquid storage device installed.

5. Dry filter:

Remove moisture and dirt from the system to prevent ice or dirt from blocking the system. Purification equipment for the refrigeration system.

6. Pressure controller:

Controls high and low pressures. When the exhaust pressure is too high or the suction pressure is too low, the controller immediately acts to cut off the pressure control circuit and stop the compressor.

7. Pressure gauge:

Pressure gauge: displays high pressure and low pressure values.

High pressure gauge range (-0.1~3.8 MPa); low pressure gauge range (-0.1~1.8 MPa).

MPa; kgf/cm2; Psi;

1MPa≈10 kgf/cm2=145Psi.

8. Solenoid valve and sight glass:

Function of solenoid valve: control the flow of refrigerant to cut off or open the liquid supply to the system.

Function of sight glass: the condition of refrigerant in liquid pipeline and the water content of refrigerant.

9. Thermal expansion valve: The thermal expansion valve controls the opening of the expansion valve through the superheat of gaseous refrigerant at the outlet of evaporator. According to different balancing methods, thermal expansion valve can be divided into internal balanced type and external balanced type.

10. Air cooler: A heat exchanger in which refrigerant absorbs heat at low temperature. In the evaporator, the refrigerant liquid coming from the expansion valve boils at a lower temperature, turns into gas, and absorbs the heat of the cooled object or medium to achieve the purpose of cooling.

According to the air convection mode, it is divided into: air cooler and coil.

11. Electrical components:

Air switch: the switch of the main refrigeration equipment, controls the opening and stopping of the system and the instantaneous internal trip protection when the system current is too large.

AC contactor: controls the opening and stopping of the compressor and fan and the defrosting of the internal heating wire of the fan.

Thermal overload relay: overcurrent protection element.

Note: The position of the warehouse temperature probe cannot make the goods press the warehouse temperature probe.

12. Refrigeration system principle:

1. After starting the refrigeration equipment, the compressor works and discharges high-temperature and high-pressure refrigerant gas; (the temperature of the exhaust pipe can be as high as 120 degrees)

2. The heat absorbed by the refrigerant in the evaporator is taken away by air (or water) through the air-cooled condenser (or water-cooled condenser), and cooled and condensed into a supercooled liquid at room temperature and high pressure;

3. Flow through the liquid storage tank, filter, sight glass, solenoid valve;

4. After the throttling and pressure reduction of the thermal expansion valve, it becomes a low-pressure and low-temperature refrigerant liquid and flows into the evaporator (air cooler or coil);

5. The refrigerant evaporates in the evaporator and absorbs the heat of the goods, thereby achieving the purpose of cooling the room;

6. The refrigerant after evaporation and heat absorption becomes a low-temperature and low-pressure gas and returns to the compressor for compression again and then discharges. This cycle repeats, and finally the temperature in the warehouse drops to the specified temperature within the specified time.

13. Defrosting of cold storage:

1. The humidity in the cold storage is different for different goods stored in the cold storage, and the amount of frost on the air cooler is also different. Therefore, different defrosting values should be set according to the different goods stored. The defrosting cycle and defrosting time set by the engineering equipment commissioning personnel during commissioning are the normal setting values.

2. Cold storage managers should frequently observe the frosting and defrosting of the air cooler, and adjust the defrosting cycle and defrosting time according to the defrosting of the air cooler, so that the defrosting can be completely eliminated without causing the storage temperature to rise too much, so as to achieve the purpose of saving electricity.

3. After the equipment enters the automatic defrosting program, the power supply cannot be turned off at this time, otherwise the defrosting program will not be able to proceed.

4. Regularly check the unobstructed condition of the defrosting water pipe to ensure that the defrosting water is transferred out in time.

5. If there is too much frost in the fan coil, forced defrosting can be performed, and manual forced defrosting can be performed for defrosting.